article by: RK

While many of us upgrade our clutches to heavy duty units due to the power increases that we add to our vehicles, it is not common knowledge that in many instances a clutch adjustment needs to be performed on vehicles that possess hydraulic clutch assemblies. When aftermarket manufacturers develop heavy duty pressure plates, they determine the amount of pedal travel that is required to support the higher pressure diaphragm. This is due to the fact that when you increase the pressure required to disengage the diaphragm, it requires more pressure from the clutch master cylinder to disengage the clutch. This can be accomplished through increasing the clutch pedal travel. Most of the time, clutch manufacturers include the specific adjustment requirements for your particular vehicle within the clutch installation instructions.

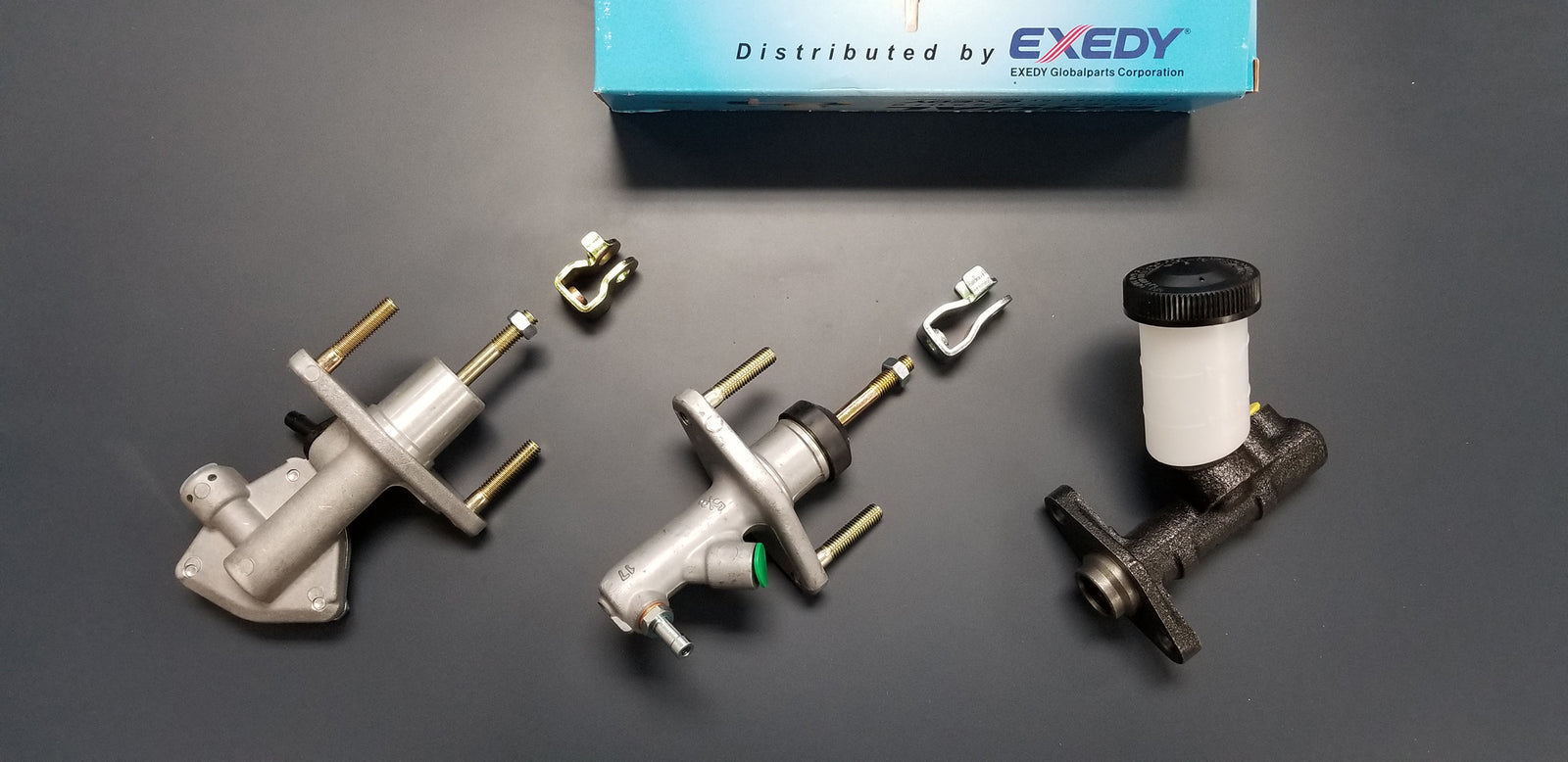

Most vehicles have adjustable clutch master cylinders, but when we are not upgrading the vehicle's performance or upgrading the clutch assemblies, unless we are replacing the clutch master cylinder, (which is highly recommended at the time you replace your clutch) we will rarely need to concern ourselves with it. On some vehicle's, there are additional components directly affected by the clutch pedal position as well. These are usually neutral safety switches and cruise control switches. When you are adjusting your pedal travel you must take these items into consideration and also make any necessary adjustments to those components as well. Also, the operation of the clutch slave cylinder travel must be considered as well. When you adjust your clutch pedal travel and master cylinder stroke, you must be certain that your slave cylinder will be able to return the fluid back into the master cylinder while your clutch pedal is at the rest position. You also must be certain that you have a minimum of pedal play, usually around a 1/16th of an inch while the pedal is at the rest position as well. Otherwise, the pressure plate will have constant pressure applied and will not fully disengage. This will result in the clutch not clamping the disc properly, premature disc and friction surface wear and the inability of the clutch assembly to provide the necessary clamping force.